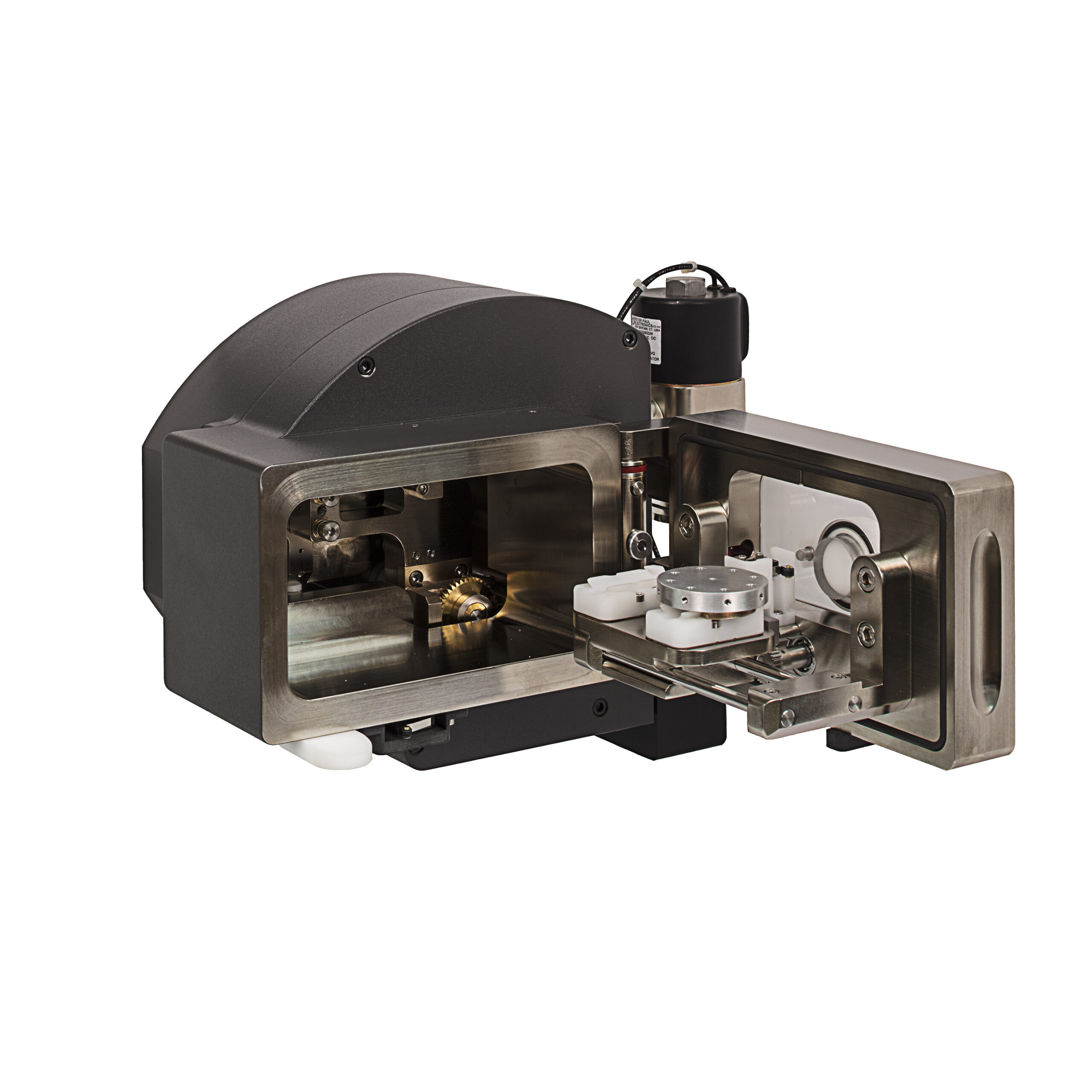

Manufacture of High Vacuum Rapid Exchange Sample Loader For The Semiconductor Industry

Alpine Precision has earned a reputation for precision electro mechanical assembly services. As a result, our company was selected to perform the assembly of this high vacuum, rapid exchange autoloader for semiconductor defect analysis. This assembly required electronics integration, cosmetic surfacing, calibration to a mock SEM, vacuum preparation, helium leak checking, packaging for international shipment

Custom control plans were developed to ensure compliance with our customer’s specifications as well as domestic and international standards. Manufacturing process plans were designed to ensure consistency between builds and copy exact compliance. Critical attention was paid to ensure cosmetically pleasing appearance of finished unit.

Project Highlights

Product Description

Housing for Z drive transmission gears.

Precision CNC Machining Capabilities Applied/Processes

Primary: CNC Milling

- Drilling

- Counterbore

- Tapping

- Reaming

- Honing

Overall Part Dimensions

Length: 4.515″

Width: 4.295″

Height: 2.330″

Tightest Tolerances

+/-.005″

Material Used

6061-T6 Aluminum

Material Finish

None

In process testing/inspection performed

Mechanical inspection

Industry for Use

SEM/FIB, Semiconductor

Volume

100/year

Delivery/Turnaround Time

3-4 weeks

Delivery Location

Massachusetts

Product Name

Housing Z Gear Drive Assembly